Installed Base Platform: The Key to Unlocking the Value of your Installed Base

May 18, 2022This blog is a precursor to an Industrial survey that I am publishing shortly where I gather data and insights from some of the leading industrial OEMs.

Aftermarket Service represents a tremendous growth opportunity for Original Equipment Manufacturers (OEMs) and their channel partners. According to McKinsey & Company, operating margins from aftermarket service can be 2.5 times higher than margins on new product sales. Indeed, many OEMs generate 40% -50% of their margins from services. Given this opportunity, almost 60% of Aftermarket Service leaders are focused on revenue growth or driving service as a profit center.

It all starts with the ‘Product Versus Service’ Mindset

Unfortunately, many OEMs struggle with growing their aftermarket business despite the promising statistics. In a recent webinar poll, I attended on Installed base data-related challenges, approximately 90% of webinar participants indicated that they face growth issues. Perhaps one of the biggest reasons for this is that building a service business requires an entirely different mindset than building a product business. Product businesses focus on the tangibles of a product, whereas service businesses focus on the intangible.

When customers purchase a product, they buy an objective reality that the product’s form, fit, and function will meet their needs. When purchasing a service, customers purchase both the reality and perception that the service will meet their outcomes. In other words, service customers purchase a defined capability of service, also known as an outcome and the actual service outcome itself. To meet customers’ expectations, service leaders must have the resources available to manage actual service production/delivery (e.g., field engineers, spare parts, etc.) and the capability to serve. In other words, they need to know what type of offers they can make and be able to deliver on them and vice versa.

The Value of Installed Base Data

Installed base data provides service leaders with the insight needed to manage the capability to serve and the actual service production. In this respect, managing a service business is more data-intensive than managing a product business. Service leaders must consider a wide range of variables in planning, managing, and executing growth objectives. installed Base data provides service organizations insight into customer requirements, utilization rates, costs, propensity to purchase, etc. This data helps service leaders research, analyze, plan, and forecast service requirements. It also provides the basis for identifying new service offerings and determining which customers are likely candidates to purchase these offerings.

The conventional wisdom among many industry analysts, software vendors, and experts is that since Aftermarket represents a significant growth opportunity, OEMs should invest in tools and technology that enable them to be more productive and provide new offerings within the Aftermarket. In other words, if you invest in the Aftermarket, your customers will come. This perspective is akin to a “field of dreams” strategy. The truth is that there’s quite a bit of work involved in building relationships, identifying opportunities, and closing sales.

Data Challenges

The core issue is that most service leaders do not have access to all the data they need to make informed decisions about their installed base or take proactive steps to increase revenue. As a result, they cannot spot trends, patterns, and opportunities. The infrastructure and reporting mechanisms are not in place to effectively complete these tasks. This situation also occurs in companies that have gone through a digital transformation.

To make informed decisions or conduct any meaningful analysis of the installed base, the typical OEM must access multiple systems and databases. It may not be unusual for an OEM to access as many as 5 or 6 different systems to obtain meaningful insight and perspectives about their installed base. For example, a CRM, ERP, Supply Chain Management, or Warranty Management software system. These systems may have been acquired or deployed over time, either through purchase or mergers & acquisitions.

Another challenge concerning the data is that multiple business functions often share it within the OEM, such as marketing, sales, finance, and quality. There may not be a single business function responsible for managing and maintaining all the data. The net effect is that it becomes a time-consuming endeavor for the service or sales organization to compile, curate, and maintain the reports they need to gain insight and intelligence into their installed base, limiting their ability to generate new revenue. In addition, the resource may not be available to perform these tasks, and the reports may not be accurate or reliable.

Installed Base Platform Benefits

Of course, within every problem lies a solution. As far as obtaining better insights into the installed base, the solution is an Installed Base Platform (IBP). An IBP is an industry-specific, purpose-built decision support system that aggregates, unifies, organizes, and analyzes IB data. This solution enables OEMs to obtain richer intelligence and deeper insight into IB to increase revenue, boost profits, and deliver an exceptional customer experience. “An IBP platform enables our company to query our IB data about anything,” notes a VP of Service at a leading OEM.

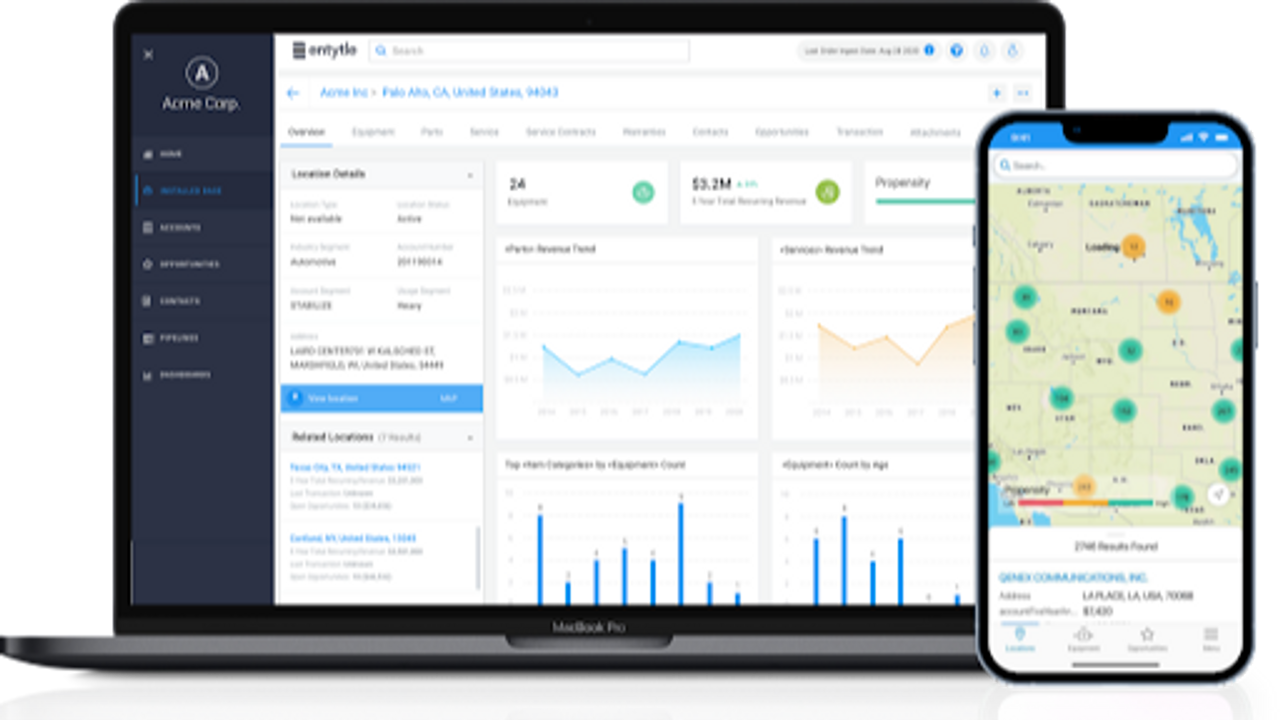

Source: Entytle’s Installed Base Platform

Companies that have implemented an IBP realize enormous benefits very quickly.

- They become more intelligent about their customer base. This transformation occurs because they gain better visibility into IB data which empowers their sales and service personnel to deliver an exceptional customer experience and drive new revenue growth.

- The IBP platform improves efficiency and productivity. A service executive we spoke to indicated that using the IBP platform enables his company to save two to three days per month generating reports. Another executive reported that the IBP enables his salespeople to be more efficient and effective at finding and closing new service revenue. As a result, his company has increased service revenue by 20% to 25% since implementing the IBP.

- An IBP can generate a high ROI. It is not uncommon for end-users of IBPs to achieve a payback within 3 to 4 months. Interestingly, that’s how long it takes to implement and stand up the solution. From a monetary perspective, there are several instances of IBP that have achieved an ROI of 10 X or higher. Given these findings, it is difficult to ignore the benefits of utilizing an IBP, particularly for managing and selling into a large installed base.

Stay connected with news and updates!

Join our mailing list to receive the latest news and updates from our team.

Don't worry, your information will not be shared.